There is plenty to consider when analyzing a transportation operation. Among the seemingly endless details that go into making a logistics decision, there is an important and often under-analyzed detail—how a carrier’s minimum charge can work in concert with retail minimum orders to maximize supply chain savings.

What Does MOQ Stand For?

MOQ stands for minimum order quantity. It is the fewest number of products that a retailer will purchase from a supplier at one time.

Though minimum order quantity and minimum charges are frequently associated with less-than-truckload (LTL) shipments, those shipping full-truckload (FTL) can also use the principle to save on transportation costs.

Minimum Charge Basics

All LTL providers have “absolute minimum charges” (AMC) – the minimum price a carrier will not go below. This means no matter how far or how much you are shipping, your cost to ship will be at least the AMC. Other factors like density, commodity type and liability play a role in LTL pricing, but AMC is where things start.

Determining how to maximize your LTL spend is essential. You may pay the same fee to move a few cases of product as you would to move a half pallet or product, leaving a significant amount of money on the table if not shipping efficiently.

Determining Your Minimum Order Quantities

So, let’s say a supplier wants to ship 10 cases of a beverage product 100 miles to a distribution facility. An LTL carrier will determine a price for that transaction based on the factors listed above.

Meaning, a carrier may determine that they are willing to haul 10 cases of a beverage product, the 100 miles it needs to go, for $100. That is the baseline charge that the carrier is willing to earn for hauling a shipment.

What many don’t realize, the carrier is likely willing to add more of a shipper’s product to their load for the exact same rate. Because the 10 cases will be hauled on a pallet, the shipper is essentially paying for the space that said pallet takes up on a truck. This means the carrier will allow a shipper to add more of their product to a pallet and then haul it, despite its weight increase, often at the same price.

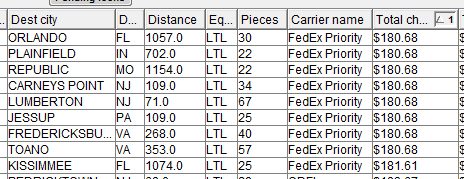

For a further illustration of the concept in action, here are a few of our customer orders where minimum charges come into play:

If you look at the shipment of 40 pieces of a commodity moving 268 miles to Fredericksburg, VA, it costs this shipper $180.68.

57 pieces of the same commodity shipping to Toano, VA, a distance of 353 miles, costs the shipper the exact same amount as a lesser quantity traveling a shorter distance.

The seemingly arbitrary price difference reflects the sometimes-strange world of minimum charges. Despite the difference in weight and distance in these hauls, each of these orders of the same commodity moving all within $1 of one another.

The same logic can be applied to full-truckload shipments. But instead of looking at increasing caseload to a pallet, shippers can sometimes add additional pallets to a truck for the same price. Meaning a shipper can often add pallets, until the truck reaches capacity, for the same price. This is because, much like LTL shipments, a supplier is paying for space on a truck.

The AMC determined by a carrier secures a truck, but it’s up to a supplier to make the most of it.

How to Set Minimum Order Quantity

Utilizing a carrier’s minimum charge specifications to your advantage requires an additional component — establishing and properly negotiating minimum order quantities with customers. The minimum order dictates the minimum quantity of a product that a brand is willing to sell as part of a single transaction.

Ecommerce can be used to explain the concept. It is unaffordable to ship a single bag of chips or a single bottle of water online. Brands often require that one or two cases are purchased before they are willing to ship a parcel, others require a price threshold be met before they will ship.

For wholesale transactions, this price point is determined during the negotiation phase of a retailer’s and supplier’s relationship.

When brands are in their adolescence, often, retailers will purchase small quantities of their products to test sell in their stores. On one hand, this is great as it gives smaller brands a chance to sell to a larger market. On the other, it can be a set-back as it may cost a supplier more to transport the product than they stand to make from the purchase.

However, that does not mean a supplier should necessarily rethink these transactions. More often than not, emerging brands will see these small product purchases from a national retailer as a necessary expense in their growth cycle.

It gives them additional branding opportunities as well as a presence in previously untapped markets. This expense, sometimes selling at a loss, can also be passed onto the sales or marketing department of an organization, as a promotional cost.

That is why it is critical to set order minimum orders that are beneficial for you as a supplier. What that means can all depend on where you are in the business cycle.

If you’re just starting to expand, it may be beneficial to set low order minimums to attract new retailers, as well as meet new order requests. If you are an established brand, you may want to set a minimum order quantity that is more beneficial to your bottom line.

We partner with brands to determine their location along the business growth cycle and what that means for their logistics strategy. Zipline Logistics can help you determine how you should be negotiating with retailers to make the most of your current relationships.

Input from Retail Buyers on Minimum Orders Quantities

Of course, the retailer has a say in what they are willing to buy and whether your ideal minimum order quantity is possible. To better understand how negotiable order quantities are, Zipline asked our network of retail buyers this question directly.

Retail buyers told us that they prefer for the conversation for minimum order quantities to happen at the start of a vendor relationship, but many shared that they are “Always willing” or “Very willing” to discuss MOQs and that this conversation can happen “whenever minimums, sales, and shelf life do not work out.”

Retailers want their suppliers to deliver product on time, in full, so if renegotiating MOQs helps achieve this goal and increase profitability, they are interested in exploring the solution.

The Importance of Cost-Per-Case

So, how do you determine your optimal MOQ for retail?

In order to do this, we look at critical metrics around your retail orders. The most important, for finding the sweet spot that both satisfies minimum order quantity specifications and a carrier’s minimum charge, is cost-per-case. It can be the difference in a successful transaction for a shipper or one that moves at a loss.

To illustrate its importance, let’s again look at our previous example. If you’re a supplier shipping 10 cases of your product 100 miles, the carrier charges you $100 for the transaction. That’s a per-case cost of $10.

Based on the way the carrier does business, that may be the best cost breakdown you can receive as the supplier. Though that’s not likely the case.

The carrier is likely willing to haul more of your product on the same truck and subsequently bringing down your cost-per-case. Say you can negotiate a purchase order to include an additional 10 cases, that cuts your cost-per-case in half. Similar transactions stretched out over a fiscal year can lead to significant supply chain savings.

Determining the minimum amount of your product you are willing to sell and ship is just one of the ways an expert 3PL firm can help improve your transportation. Zipline’s data application, called KanoPI, can help isolate this important metric for your organization and further the conversation about its importance.

Putting It All Together

Whether an emerging brand or an established player in the market, retailers do not always write purchasing agreements that favor suppliers.

It is critical to identify the important metrics and areas of improvement needed to create long-term profitability with a retail order. Or, at the very least understand the benefits of shipping at a loss to certain retailers for what will eventually translate into a long-term win for your brand.

We work with both up-and-coming suppliers and well-established brands to determine the best action plan regarding your national retail transportation.

It is imperative that you have logistics conversations with a trusted 3PL like Zipline prior to negotiating minimum order quantity agreements with buyers. If you’d like to speak with one of our expert logistics consultants about retail transportation today, reach out to schedule an introduction.