As automation and artificial intelligence (AI) move from buzzwords to business necessities, logistics leaders are asking a simple question: what actually works?

On a recent episode of TRUCK YEAH!, Zipline Logistics sat down with Brent Hagan, Chief Supply Chain Officer at Lob, to talk about robotics, AI, and what it really takes to run high-efficiency logistics networks at scale. With experience spanning Amazon’s top-performing robotic fulfillment centers, Deliverr’s rapid expansion through its Shopify acquisition, and Lob’s global print-to-mail operation, Brent brought a grounded, operator-first perspective to the conversation.

Here are the key takeaways logistics professionals, carriers, and CPG shippers should know.

Robotics Don’t Replace People, They Redesign the Work

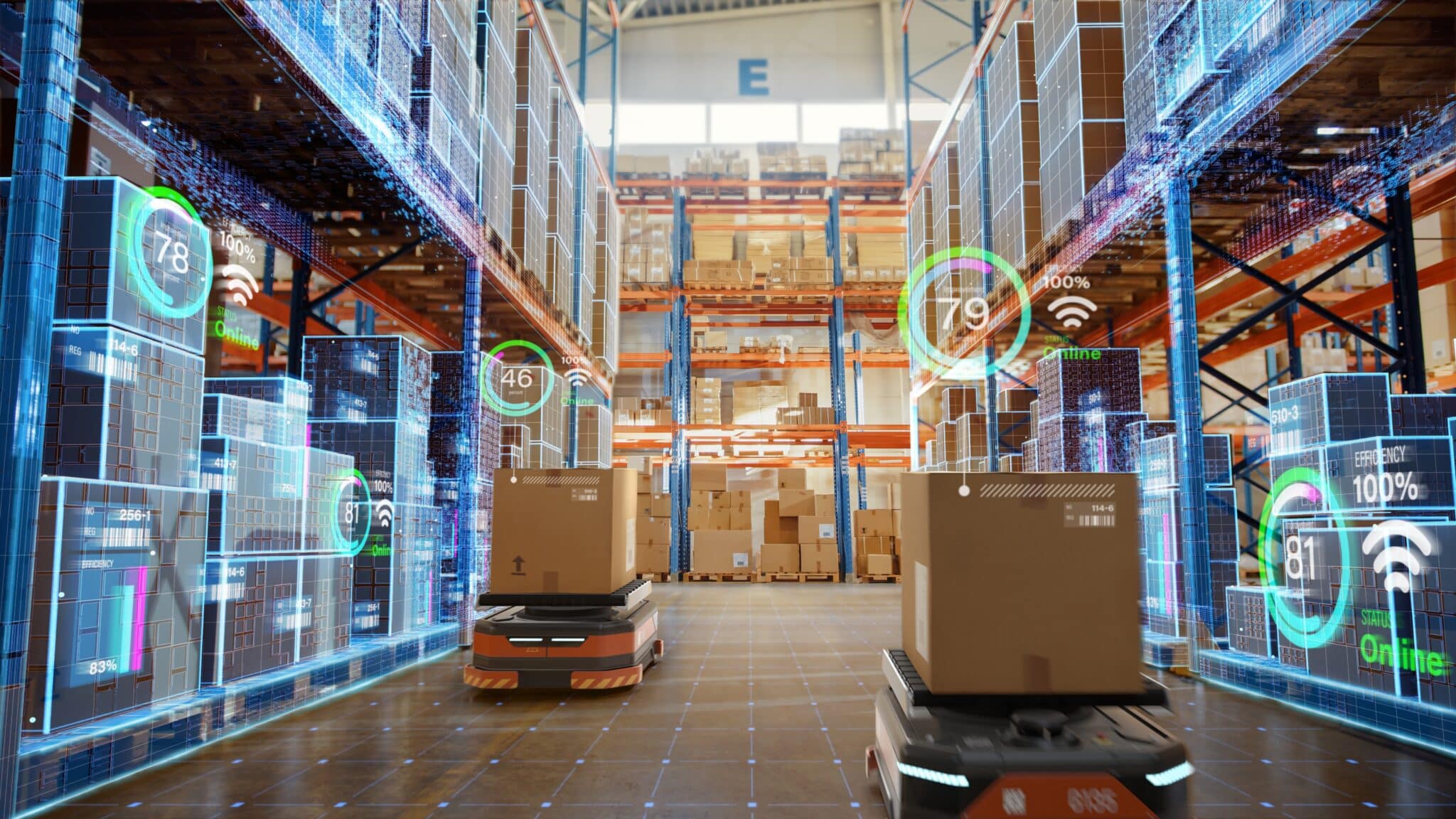

Brent has overseen facilities with more than 13,000 robots operating on-site. One of his clearest messages throughout the episode was this: robotics aren’t about removing humans from the equation.

Instead, automation simply shifts where and how people create value. Robots handle repetitive, physically demanding, or high-precision tasks, while humans move into roles that require judgment, coordination, and problem-solving.

From a logistics standpoint, this redesign shows up downstream:

- Faster, more predictable throughput

- More consistent dock schedules

- Reduced variability during peak seasons

For carriers and drivers, automated facilities often mean tighter appointment windows, but also fewer surprises once you’re on-site.

AI is Only as Good as the Data Behind it

AI can forecast demand, optimize routing, and flag disruptions before they escalate. That is, if the underlying data is reliable. Many organizations want AI to be the fix before they’ve done the foundational work of cleaning up data and standardizing processes. Without that groundwork, AI simply scales inefficiency faster.

The real opportunity today isn’t flashy algorithms. Instead, it’s:

- Better visibility across the network

- Clearer signals around inventory and order cadence

- Earlier warnings when something starts to drift off plan

For logistics leaders, AI works best when it supports decision-making rather than trying to replace it.

What Highly Automated Facilities Mean for Truckers

Automation changes the rhythm of a warehouse, and that matters to drivers. The most efficient robotic facilities are designed around flow, from inbound receiving to outbound shipping.

When that flow works, carriers benefit from:

- Faster turnaround times

- Less congestion at docks

- Clearer expectations for arrivals and departures

But when systems aren’t aligned, automation can amplify bottlenecks just as quickly as it solves them. Communication and carrier partnerships become even more critical in these environments.

Postal Logistics and Freight Face the Same Peak-Season Pressures

At Lob, Brent manages a global network that produces and delivers billions of personalized mailpieces through USPS. While mail and freight may seem worlds apart, the operational challenges are surprisingly similar.

Both systems must contend with:

- Seasonal volume spikes

- Tight delivery windows

- Capacity constraints across transportation networks

Peak-season success is all about early planning, realistic capacity assumptions, and partners who can execute under pressure.

Embracing AI is Now a Competitive Advantage

AI won’t replace you, but someone who knows how to use it might. In logistics, the winners won’t be the companies with the most technology.

The winners will be the ones who:

- Adopt tools intentionally

- Train teams effectively

- Use automation to enhance (not complicate) operations

Whether it’s robotics in fulfillment centers or AI in planning and forecasting, technology works best when it’s paired with experienced operators and clear objectives. Robotics and AI are no longer future-state concepts. They’re here, they’re evolving fast, and they’re reshaping how freight, mail, and fulfillment move every day.

The real gains come from focusing on efficiency, data quality, and people. For truckers, CPG shippers, and logistics professionals alike, understanding how these tools change the flow of freight is key to staying competitive in an increasingly automated supply chain.

Want to hear our full conversation with Brent? Check out the complete episode of TRUCK YEAH! featuring Brent Hagan for more real-world insights from inside high-performance logistics networks.

KANOPI: Zipline’s Proprietary Shipping Intelligence Tool

Built in-house and improved daily by the Zipline Development Team, KANOPI is our proprietary shipper intelligence tool. Our retail logistics experts leverage KANOPI to optimize client supply chain efficiency, reduce costs, and skyrocket logistics performance.

KANOPI has helped Zipline clients achieve up to:

- $1.2 Million in transportation savings

- 20% reduction in cost per pallet through consolidation

- 17% improvement in meeting on-time in-full delivery (OTIF)

- 30% increase in network efficiency

- 861,908 fewer projected miles traveled overall

KANOPI provides Zipline clients with:

- High-powered visibility and data to track and trace shipments

- Weather overlays and proactive alerts of potential disruptions

- Reports on logistics performance and cost analyses to make timely, cost-effective decisions

- Queries and sorts data so users can identify new opportunities